Mobile version

Micro Station

Our produced a 4-72 series plastic centrifugal fan, with a hard polyvinyl chloride (PVC) or hard polypropylene (PP) sheet, by hot pressing, welding Seiko produced. The fan belongs to the low-pressure fan type, widely used in chemical industry, metallurgy, electronics, instruments, electroplating, textile, medicine, scientific research, environmental protection, public places, restaurants and ventilate, excluding containing acid, alkali and toxic gases indispensable equipment.

The factory combines the advantages of domestic similar products, constantly sum up, improve, improve, improve on the basis of product quality, after 10 years of practice have proved that I plant a series of plastic centrifugal fan compared with similar products, with high efficiency, low power consumption, corrosion, attractive appearance, low noise, fastness, does not require frequent maintenance, etc., by the user's letter Angels and praise.

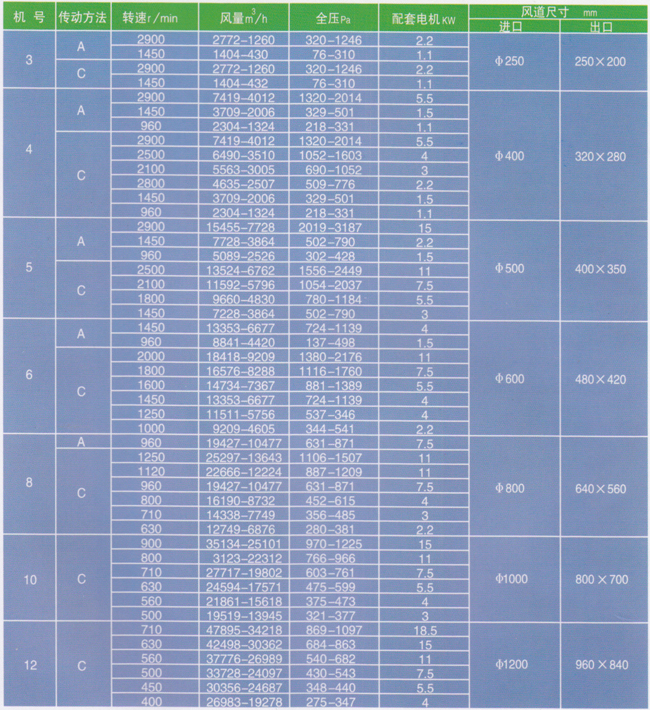

Fan machine number and performance:

A fan of the machine number: I plant now 4-72 plastic fan series, a total of eleven machine number, sixteen kinds of specifications. Machine number is based on the work of the fan impeller diameter may be (for example: NO-41 for impeller diameter of 400mm).

Second, the transmission type: Factory production of plastic centrifugal fan 4-72 series direct-drive motors are used. Namely "A" type transmission, can be used "B" type transmission and "C" or "D" type transmission according to the special needs.

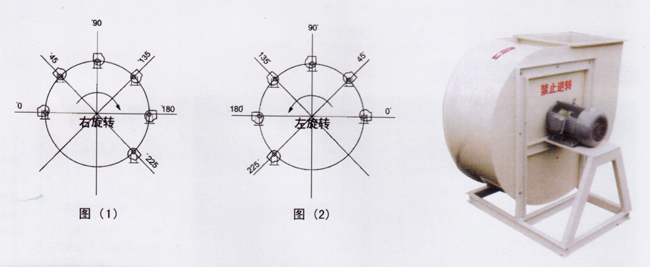

Third, the rotational direction of the fan and the outlet point: Our production fan is divided into right rotation and left rotation in two forms, namely from the motor - side, the work of the impeller rotates clockwise, as the right rotation with the "right", said : counterclockwise rotation from the motor front end, said left rotation, use the "left".

Users outlet angle according to the site, and production needs in the 0 ° -225 ° between six different angles (see ①, ②) choose (not specified when ordering are the right 90 ° standard default.)

Installation and maintenance of the fan:

1, the fan installation, must be based on a solid fan base surface and to maintain the level, you must use foot bolts, preventing vibration.

2, the installation of ventilation ducts its weight can not be loaded on the blower, so as not to damage the casing deformation.

3, after the fan is installed, you must check whether the foreign body within the cabinet to avoid unnecessary damage.

4, to periodically check the internal fan, if the impeller sticky particles exist, must be promptly removed.

5. To check the motor bearing internally lubricated regularly.

6, when the wind turbine installation, import and export, piping and fans mouth, soft contact must prevent resonance, affect fan operation.

Fan model and Performance Specifications:

Note: A formula for the direct drive motor pulley drive C formula

Precautions:

1, due to hard PVC, hard PP, plastic strength inferior metal material, so fans in the installation, pay special attention to light unloading light up. Do not crash, to avoid damage.

2. Check all parts before installation, a crack is found, damage repair and replacement should be timely, proper inspection before installation.

3, the fan should be in PVC, PP provided for the gas for the media in use does not allow the use of viscous and particulate matter in the gas.

4, factory production of PVC plastic wind Rongji, the use of temperature between -5 ℃ ~ 40 ℃, PP plastic fan, use temperature between -10 ℃ ~ 80 ℃.